The AR-10 versus the FN FAL: tactical and technical requirements, 1961

×

![]()

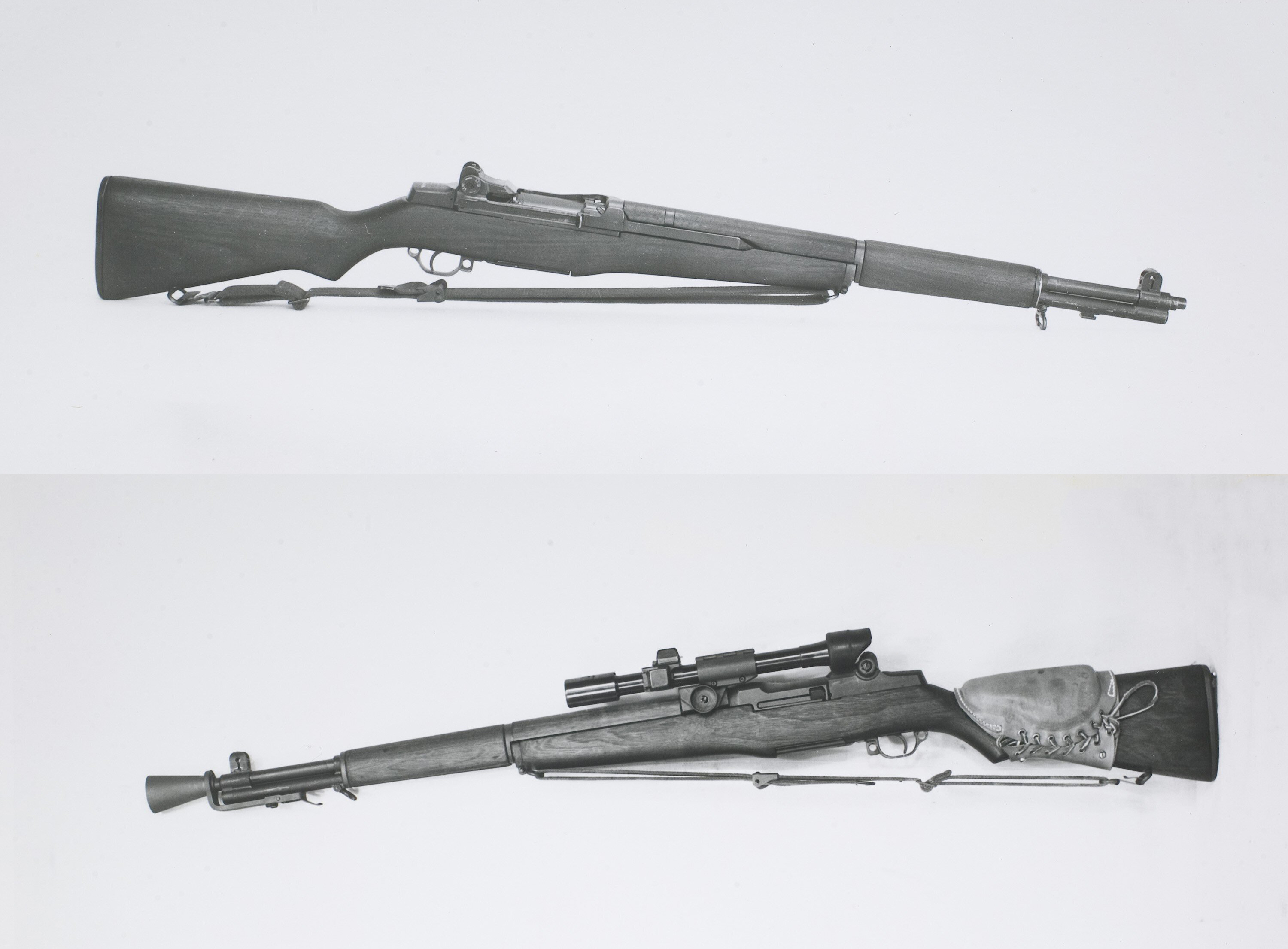

The rifles that would be trialled: the Fabrique Nationale de Herstal

Fusil Automatique Léger (FN FAL) and the Artillerie Inrichtingen AR-10. Note that this is not

the final model of FAL as it would be adopted, differing with regards to its sights, carrying handle, and sling arrangement.

Introduction

This article is a follow-up to a previous article on the AR-10, found here. Whilst the documents cited in the aforementioned article concern an early trial by the Dutch Marine Corps in 1957, the documents discussed below were drawn up by the Dutch Landmacht (Army) in 1961.At this point in time, both the Army and Marines found themselves engaged in low-intensity warfare against Indonesian "infiltrators" (i.e. paratroopers, special forces and marines) equipped with a varied mix of old and modern weapons.

Armed for the most part with WWII-vintage weaponry - M1 carbines, M1 Garands, Bren guns or Browning Automatic Rifles - the Army and Marines did not necessarily have a firepower advantage during these small skirmishes. One veteran would describe the modifications to the standard Dutch marine rifle squad as such:

Organically, a rifle squad of 13 consisted of three automatic rifle teams with a single BAR plus three M1 Garands each. Only the squad leader carried an Uzi. Soon, every automatic rifle team carried a second BAR. After we had captured large numbers of Indonesian weapons, the M1 Garand was replaced by Thompsons and AK47s, to the point where there was a single Garand to a squad. This for firing Energa rifle grenades, as these were often used. The fact that the standard rifle squads were almost exclusively equipped with automatic weapons meant they had excellent firepower.

A representative image of weapons captured from Indonesian "infiltrators", 1962: multiple AR-15s, a CETME rifle, a Bren LMG, a

Husqvarna submachine gun, multiple revolvers and a semi-automatic pistol.

With this context in mind, let us examine the documents themselves, found at Nationaal Archief, Den Haag, Inspecties van de Wapens en Dienstvakken van de Koninklijke Landmacht, nummer toegang 2.13.158, inventarisnummer 1146: Beproevingseisen van infanteriegeweren op tactische en technische punten. 1961.

Requirements

Principles, for the assessment of infantry rifles on tactical and technical aspects.Purpose

Adopting a rifle as an individual combat weapon;

- with which the 7.62 mm NATO cartridge can be fired both in [fully-]automatic and semi-automatic modes;

- with which both anti-tank and anti-personnel rifle grenades can be fired;

- which, equipped with a bayonet, can be used as a melee weapon;

- which is equipped to accept a scope and infra-red sight.

The rifles to be replaced: the M1 Garand and M1D Garand. These rifles would be pushed down to territorial units to replace the worn-out Lee-Enfield rifles.

1. General requirements.

1.1. The rifle must be capable of:

- firing 7.62mm NATO in both [fully-]automatic and semi-automatic modes;

- firing anti-personnel and anti-tank rifle grenades;

- the requirements which apply to the above have been internationally agreed upon.

1.2. The weapon must be capable of mounting:

- a scope;

- infra-red equipment [i.e. infra-red night sights, infra-red light sources, battery];

- a bayonet;

- a bipod;

- a blank-firing adapter which allows semi-automatic functioning.

1.3. The rifle must have an effective range of:

- 300m, using the standard sights;

- 600m, using a telescopic sight;

- 100m, using anti-tank rifle grenades;

- 400m, using anti-personnel rifle grenades.

Technical trials.

| Requirements. | Trial procedure. |

|---|---|

| 2. Accuracy The rifle must, with good ammunition, be capable of a. firing semi-automatically: - at 200m without telescopic sight, with half of all rounds landing in a square whose circumference is less than 40cm. - at 600m with a telescopic sight. |

Groups will be fired at 200 and 300m with 7.62mm NATO rifles, in comparison with the American M1 (Garand). The weapons will be fired prone, supported on sand bags. Three series of 10 rounds, semi-automatic. Vertical and horizontal spread will be measured in millimetres. This trial will also be performed at 500m.

Riflemen: 5 trained riflemen. Groups will be fired with telescopic sights at 600m and 800m. The weapons will be fired prone, supported on sand bags. Two series of 10 rounds, semi-automatic. A standing man (chest-size target) must be hit. |

| b. firing [fully-]automatically: - at 50m, from the hip, with accuracy which at best, approaches that of the current 9mm submachine guns; - at 300m, equipped with a light bipod and without barrel change [mechanism], if possible approaching the accuracy of the BREN or B.A.R. |

Groups will be fired from the hip at 50m with 7.62mm NATO rifles and the STEN and UZI submachine guns. Three series of 20 rounds will be fired in bursts of approx. 3 to 4 rounds. The number of hits on a chest-size target will be counted. Groups will be fired at 300m using the 7.62mm NATO rifles equipped with bipods, BREN and B.A.R. Three series of 20 rounds will be fired in bursts of approx. 3 to 4 rounds. Vertical and horizontal spread will be measured in centimetres. |

| 3. Handling 3.1. Maximum weight. Approx. 4 kilogrammes, without magazine, bipod, bayonet, or rifle grenade launcher. 3.2. Maximum length less than 110 centimetres. Keeping in mind the need for a variant for special troops, which allows the weapon to be transported in some manner with a total length of 70 centimetres. All other requirements still apply. |

Such a model was not trialled. |

| 4. Solidity and resistance against wear. The weapon must be of a simple construction. The production process must be simple. After 20.000 rounds, no principal component – receiver, bolt, bolt carrier or bolt components – may be broken or worn. The barrel life must be at least 15.000 rounds. Screws, bolts, pins, and fasteners must be – as much as possible – of a standard type and of as little variation. |

Longevity trials: Longevity trials are performed with the weapons placed in spring-loaded mounts. Method: 15.000 rounds in series of 100 rounds. After every 100 rounds, the weapon is allowed to [air-]cool. For the purpose of this trial, and after every 1,000 rounds, the following measurements are taken: 1. Muzzle velocity. 2. Rate of fire. 3. Groups size: range: 50m, standing, supported, series of 10 rounds. 4. Barrel wear measured with cylindrical gauges, sizes ascending by 0.01mm. 5. Head-space. |

| 5. Functioning. The weapons must function with all ammunition types which satisfy NATO-requirements, without jams, at temperatures of + 52 degrees Celsius to - 40 degrees Celsius. The replacement of parts is not allowed. In case a weapon is gas-operated, regulation of the gas mechanism must be easily user-adjustable. Automatic fire must be possible with a blank-firing adapter. |

Functioning trials. 1. Various types of ammunition. Tested manufacturers: AI. Staatsbedrijf Artillerie Inrichtingen. FN. Fabrique Nationale (Belgium) ICI. Imperial Chemical Industries (England) FF. Försvarets Fabriksverk (Sweden) DAG. Dynamit-Action-Gesellschaft (Germany) LC. Lake City (USA). It has not been investigated whether these cartridges satisfy NATO-requirements. a. Velocity measurements. A rifle of every type will be used to fire two series of 10 rounds of every ammunition type for the purpose of measuring velocity. b. Grouping. A rifle of every type will be used to fire a two series of 10 rounds of every ammunition type for the purpose of measuring group size. c. Functioning trials. Per type of weapon 480 rounds, divided among two rifles. Per weapon: 120 rounds semi-automatic and 120 rounds [fully-]automatic. The weapon will be held at different angles during firing. During automatic firing, the weapon will be held horizontally to determine the rate of fire. 2. Firing trial at high temperatures. The weapon will be loaded with a full magazine and kept at a temperature of plus 60 degrees Celsius for 16 hours, after which it will be fired immediately at normal temperatures. 3. Firing trial at low temperatures. As described under point 2, though at minus 40 degrees Celsius. |

| 6. Safety. A loaded rifle with its fire selector or safety set to “fire” must not discharge when it is hit, smacked, or dropped. |

Safety:

A sample of every type of weapon is loaded with a magazine containing two blank cartridges and another blank cartridge loaded into the chamber, with the fire selector or safety set to “fire”. The weapon will be dropped from 2.5m high onto a flat slab of concrete from a number of initial positions. a. Vertical, buttstock facing down b. Horizontal, left side facing down c. Horizontal, right side facing down d. Horizontal, bottom side facing down e. Horizontal, top side facing down f. Vertical, barrel facing down |

| 7. Reliability. The weapon must be capable of firing when fouled by water and/or sand, and powder residue. |

Reliability: 1. Sand test Of every type of weapon, two were tested, that is: one weapon with a loaded magazine without a cartridge in the chamber, and one with a cartridge in the chamber. The weapon is tested by introducing compressed air to a box of sand, in which the weapon is placed alternating between its right and left side. The barrel is plugged. Time: 2 minutes per side. 2. Mud test Weapon is in a state as under point 1. The weapon is tested by submerging it in a thin, liquid pool of mud, which is kept at a flow through stirring it. The barrel is plugged. 3. Sea water test. The weapon, loaded and with a full magazine, is submerged in sea water and without being cleaned, stored in a room at 20 degrees Celsius at 80% humidity. Thereafter, the weapons are tested by firing them. |

| Rifle grenades. The weapon must, without receiving damage – especially breaking of the stock – be capable of firing an anti-tank rifle grenade weighing 800 grammes with a muzzle velocity of ±50 metres per second and an anti-personnel rifle grenade weighing 500 grammes with a muzzle velocity of ±70 metres per second. |

Rifle grenade firing trials. 1. Investigate the rifle with regards to the stock’s mounting point to the receiver, the buttplate, lower front handguard, rifle grenade launcher, and a general visual inspection. 2. Grouping with 7.62mm ball rounds. Weapon mounted in a precision vice which allows it to recoil. Three groups of 20 rounds at 50 metres. Check the mean point of impact in relation to the point of aim. 3. Strength firing trial with rifle grenade. Per weapon, 10 practice rifle grenades with a weight of 800 g. and 10 practice rifle grenades with a weight of 500 g. are fired with muzzle velocities of ±50 and ±70 metres per second respectively. The trial is performed twice for each rifle: a. The buttplate is supported at the top. b. The buttplate is supported at the bottom. The weapons are placed in a special vice allowing the stock to be supported as described above. 4. Inspection of the rifles. 5. Grouping, as under point 2. |

The AR-10 and FN FAL during trials, with their respective optics, the AI-62 scope and OIP scope.

8. Technical specifications of the rifles.

General: All controls must be of such a shape and size so as to allow operation with winter gloves.

8.1. Sight.

The sight must be of the aperture type.

The sight must be optimal for both daylight and low-light conditions.

If the front sight is adjusted horizontally, the front sight protector must move with the front sight.

No more than one front sight post size is allowed.

Setting the sights must be easily accomplished with a simple tool, not allowing the rifleman to disrupt the sights once set.

Horizontal adjustment by the user for the purpose of adjusting for wind and such is not desired.

The rifle grenade sight must be attached to the weapon in such a way as to allow firing at ranges of 25, 50, 75, and 100 metres for the anti-tank rifle grenade, and to-be-determined ranges for the anti-personnel rifle grenade.

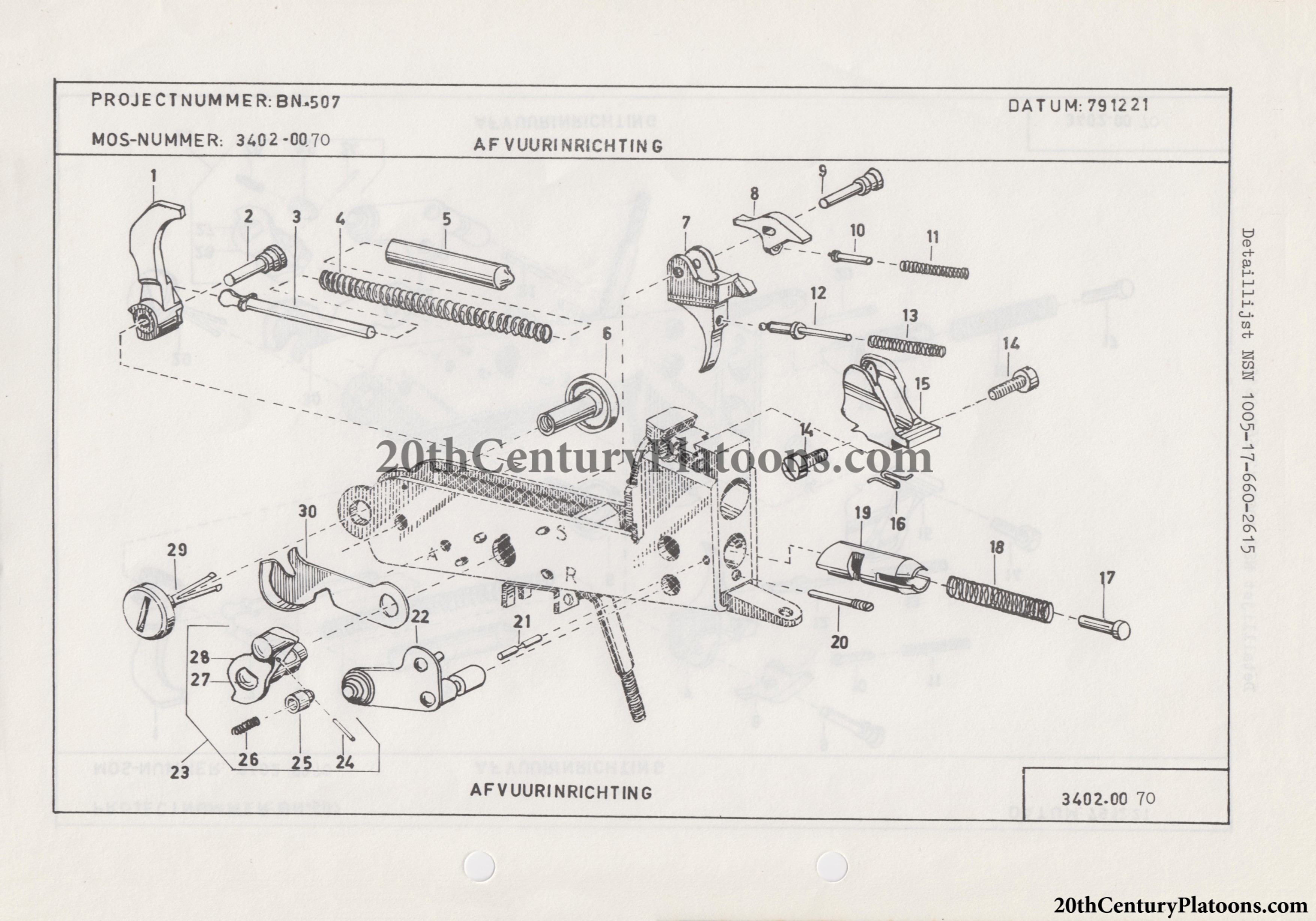

An exploded view of the receiver. Note the sight, specific to the Dutch model.

8.2. Trigger mechanism.

The trigger mechanism must be of a simple construction and allow for easy and tool-free assembly and disassembly by cadre [i.e. non-conscript, professional] and 2nd echelon [company-level] maintenance personnel.

Trigger pressure must be between 2.5 and 3.5 kilogrammes.

The positions of the fire selector – that is, safe, [fully-]automatic and semi-automatic fire – must be marked with respectively [in English] “safe”, “auto”, and “semi”.

When switching from one mode of fire to the other, the fire selector is not allowed to easily slip past the intended mode.

The mechanism to limit fully-automatic fire must be easily installed and removed.

The weapon must be easily loaded, reloaded, and unloaded when it is set to safe.

8.3. Hold open device.

A hold open device must be fitted.

This device is to hold the bolt in the rearward position, in case the magazine has been emptied.

8.4. Carrying handle.

The carrying handle must be attached to the weapon in such a manner that the weapon with a loaded 20-round magazine is in balance, or to allow the barrel to point up ever so slightly.

8.5. Sling swivels.

The sling swivels must be placed on the left side of the weapon, in such a way as to allow the weapon to carried flat against the body with the buttstock pointing up and in such a way as to prevent abnormal wear to the sling.

The sling swivels must be sufficiently strong to handle the force, which is generated when rifle grenades are fired.

8.6. Buttstock.

The stock’s length must be suitable for the average soldier.

8.7. Magazine.

The weapon must be fed by a 20-round magazine, which can be quickly changed.

The magazines must able to be filled quickly by means of:

a. single cartridges

b. a simple magazine loading tool (maximum weight 75 grammes) and a charger.

This charger must satisfy NATO requirements.

8.8. Rifle grenade launcher.

The rifle grenade launcher must have an external diameter of 22 millimetres.

8.9. Telescopic sight mount.

The telescopic sight mount must be able to accept a telescopic sight and infra-red sight.

When a telescopic sight or infra-red sight has been placed, the standard sights should remain usable up to a range 400 metres for the purpose of zeroing the optical sights without firing.

8.10. Markings.

The complete serial number must be marked on the receiver. The markings – concerning other parts as well – must be as such that they can be read quickly.

The letters and numbers of the serial number must have a height of 3 millimetres. Factory markings, the weapon’s name and possible model numbers must not hamper the reading of the serial number.

The weapon’s name must be marked, as is the calibre “7,62 mm, NATO”. Possible model numbers may be applied following this.

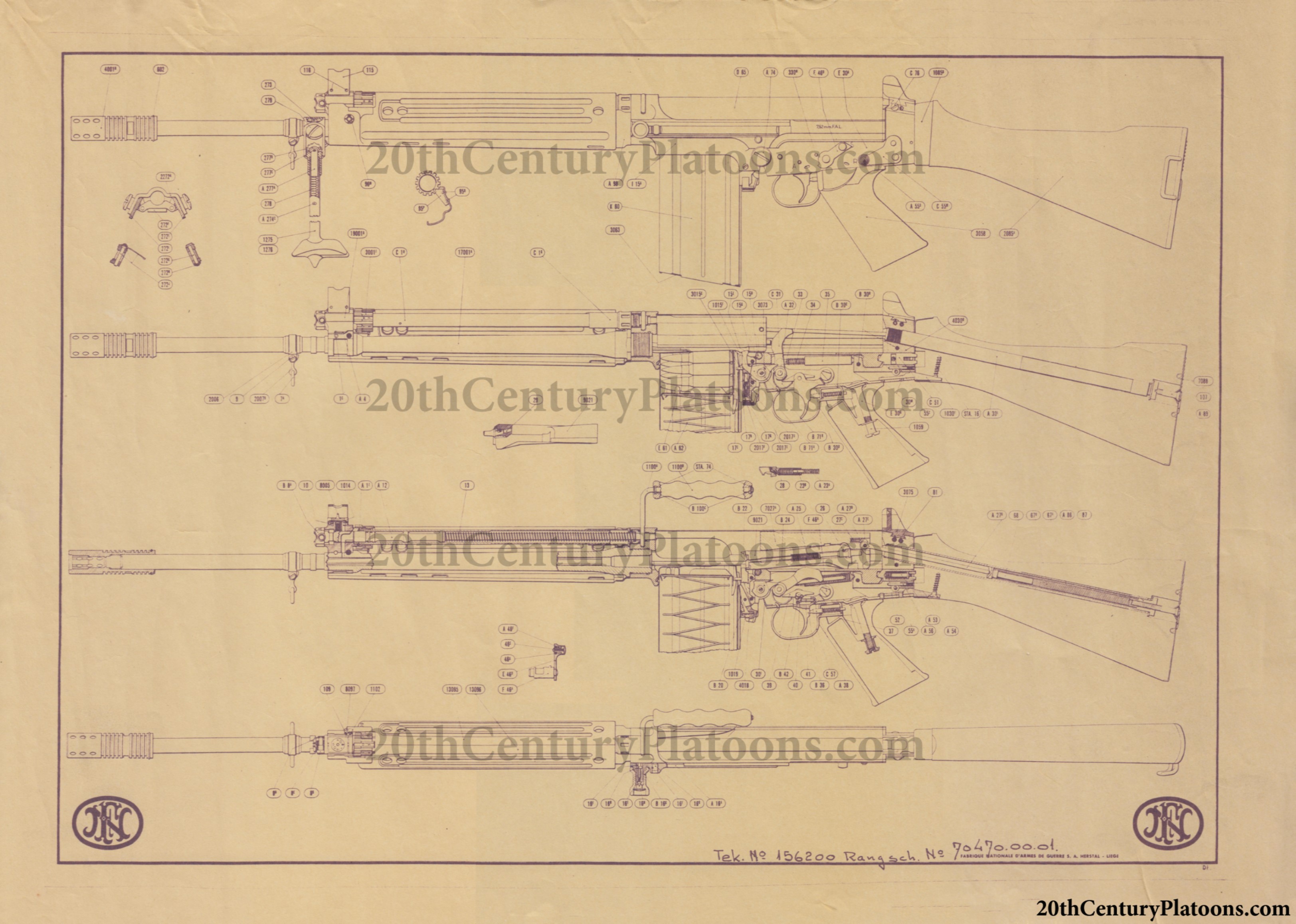

A technical drawing of the FN FAL as adopted.

8.11. Bayonet.

The bayonet must function as a knife and dagger.

The blade’s length must be – tip to guard – 15 centimetres.

With the bayonet mounted, the front of the guard may not be removed from the muzzle by more than 1 centimetre.

The guard may not damage the rifle grenade launcher’s ribs.

The mounted bayonet may not influence ballistic performance in a noteworthy manner.

Only a small, constant deviation from the mean point of impact is allowed. The bayonet must fit the weapon in such a way, that it is not required to number the bayonet to the weapon.

The bayonet must be phosphated.

8.12. Bipod.

The bipod must be easily attached and removed.

8.13. Blank-firing adapter.

The blank-firing adapter must be clearly visible when attached to the rifle.

The blank-firing adapter’s threads must not become unusable as a result of firing.

8.14. Oil bottle.

It is desirable an oil bottle with a maximum length of 145 millimetres and a maximum diameter of 19 millimetres can be stored in the weapon.

9. Maintenance.

9.1. Maintenance must be simple at all levels. Spare parts must be installed with as little modification as possible and the necessary maintenance tools must be kept to a minimum.

9.2. The user’s combination tool for assembly and disassembly must be simple, compact, and light. The number of parts must be kept to a minimum.

9.3. All parts of the weapon which are exposed to moisture, sand, mud, and powder residue must be easily accessible.

9.4. It must be possible to undertake maintenance using OX-52; OX-13; PX-7; PX-1, and white gas/naphtha. The weapon’s components must be resistant against these products.

9.5. Cleaning tools such as cleaning rods and pull throughs etc. must be of standardised types.

9.6. It must be possible to preserve the weapon without using special facilities by using PX-1, after which the weapon must be ready to fire without washing the weapon in solvents.

9.7. No form of corrosion may occur when the weapon is stored after applying PX-1.

10. Materials and finish

Buttstocks, handguards, pistol-grips, and carrying handles must be made of plywood, rubber, polymer, or metal.

Finishes applied to protect the weapon must not wear, be resistant against long-term use, and not stain.

The finish should be unaffected by the usual cleaning equipment.

The adopted rifle

Whilst the story of the actual trials and the consequent adoption and service of the FN FAL are beyond the scope of this article and are saved for later, it is worth discussing in brief.

A Dutch marine seated in a Land Rover aims his FAL. Note the front and rear sights.

With the AR-10 performing exceedingly poorly during trials - despite the Dutch military favouring it to some extent as a domestic rifle - the FN FAL was ultimately adopted.

Distinguishing features are the shielded rear and hooded front sight, metal handguard, bipod, and integral rifle grenade launcher muzzle device. The metal handguard and wooden stocks would be replaced by polymer variants in the 1980s and 90s. In the marksman role, it would not be adopted with the offset Belgian OIP scope, but rather, the Dutch AI-62 scope.

The following overview illustrates some differences between the adopted variant and the requirements:

| Requirement no. | Requirement | Adopted FAL variant |

|---|---|---|

| 1.1 | The rifle must be capable of firing 7.62mm NATO in both [fully-]automatic and semi-automatic modes; | Locked to semi-automatic fire |

| The rifle must be capable of firing anti-personnel and anti-tank rifle grenades; | Not equipped with anti-personnel rifle grenades by the Army and Navy | |

| 3.1 | Maximum weight. Approx. 4 kilogrammes, without magazine, bipod, bayonet, or rifle grenade launcher. | Approximate weight of 4.3 kilogrammes, integral rifle grenade launcher. |

| 3.2. | Keeping in mind the need for a variant for special troops, which allows the weapon to be transported in some manner with a total length of 70 centimetres. | No special variant was ever adopted. Instead, the Uzi submachine was used as a general carbine/personal self defence weapon for support units. |

| 8.2 | The positions of the fire selector – that is, safe, [fully-]automatic and semi-automatic fire – must be marked with respectively [in English] “safe”, “auto”, and “semi”. | The receiver was marked in the British fashion, that is, Safe, Automatic, and Repetition. |

An excellent weapon, the FAL was used as the service rifle until 1995 when it was replaced by the C7/C7A1 Diemaco.

Reservists would follow two years later, the same year in which the AI AWM .338 rifle would replace the FAL in the marksman's role.

Still, the scoped FAL would continue in service until 2010 with the ISAF Battlegroups. The final rifles were - reportedly - donated to the Kurds as aid in 2014.

The FN FAL with AI-62 KRR in service in Afghanistan.

Original document